Handwerk

Betonprojekte

Bis 2018 haben wir nicht nur eigene Produkte hergestellt, sondern auch ganz klassische Auftragsarbeiten angeboten. Unser Projektportfolio umfasst Groß bis Klein. So haben wir beispielsweise schon mehrere Betontheken, Arbeitsplatten aus Beton und Fliesen aus Beton für verschiedenste Auftraggeber gegossen. Aber auch Designobjekte, wie den Nike Air Jordan 4 „Cement“ haben wir aus Beton hergestellt. Hier findest du eine kleine Auswahl unserer damaligen Betonprojekte:

we are making history

Our most special memories

A look into

our manufactory

Made in Germany

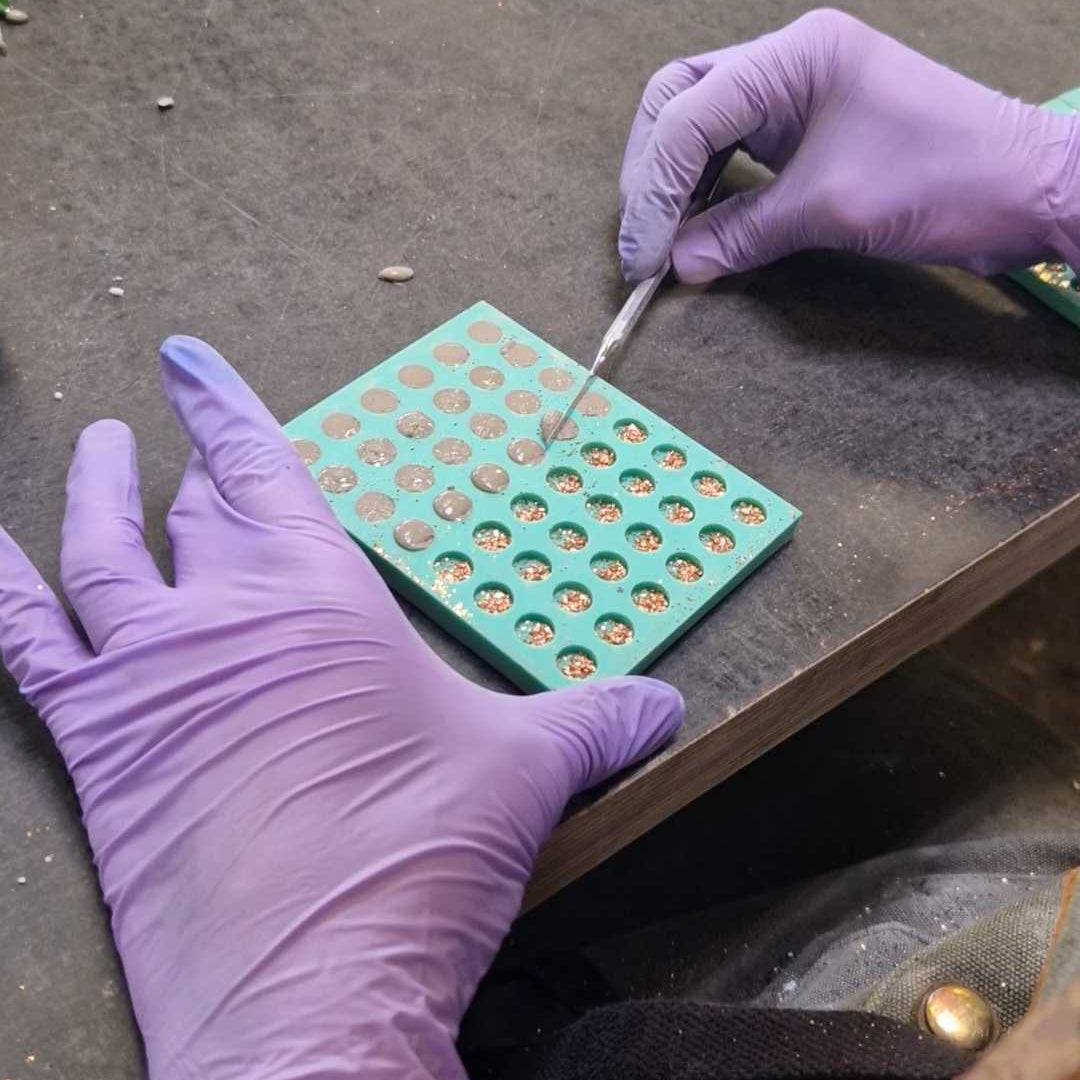

Our concrete manufactory is located in Germany, more precisely in Frankfurt am Main. All of our products are handcrafted by our Concrete Jungle team. It was important to us to remain a craft company despite e-commerce and to produce the products ourselves. Not only because we think it's an incredible shame that many crafts in Germany are increasingly dying and more and more production is being done abroad, but also because our founders themselves enjoy working and like to put on their aprons from time to time.

Quality through honest craftmanship

Because we produce everything ourselves in our manufactory, we can ensure that the quality of our products always meets our requirements. A product goes through up to thirty work steps and twelve hands. Everyone has an eye for detail and checks every piece for quality. We always make sure to pay our employees fairly and offer them a creative place to work.

THE MANUFACTURY IN MOVING IMAGES

Our special materials

Our most distinguishing feature is combining different materials, which themselves are also exeptional.

The concrete

Our specially developed concrete contains the best ingredients, such as marble powder and marble sand, also known as the highest quality Portland cement (52.5 R). Through our years of testing, we have developed a concrete that is not only particularly light and comfortable to wear, but also extremely durable. The compressive strength of our recepies is between 100 – 130 N/mm2. Our pieces of jewelry can withstand up to 10 falls from a height of 2m, even though our jewelry is only 2-4mm thick.

The finishing

But that's not all: we only refine our jewelry with the best precious metals or even gemstones. And here too we look at sustainability. For our most famous Grey Rosé collection, for example, we use recycled copper that we obtain from old power cables. This creates an unmistakable composition of mat concrete and sparkling copper crystals.

The silver

Our founder Madlen herself suffers from a nickel allergy. That's why it was natural for her that all of our jewelry should be nickel-free and made of 925 sterling silver. It was important to us to attach importance to sustainability here and to do it better than many other jewelry labels. That's why our sterling silver is recycled and comes from the regional precious metal company Heraeus, based in Hanau.

Unique jewelry

Our craft and special technique to combine the materials with concrete means that each piece is unique. Not one is exactly the same as the other. This makes our jewelry really special compared to usual jewelry. Every single piece reflects the uniqueness of every person and is therefore a wonderful gift for our loved ones. Some of our customers even see shapes or figures in the patterns and say it's like watching clouds. Everyone's imagination is stimulated and invites them to dream.